Product Description

ht 850 metal sheet corrugated roof roll building machine

Name |

crimped roll forming machine |

application |

roof panel |

color |

any |

warranty |

1 year |

ling speed |

12-15m/min |

certification |

ISO9001:2008 |

specification

Material of frame |

(high grade) 250mm I shape steel welding

|

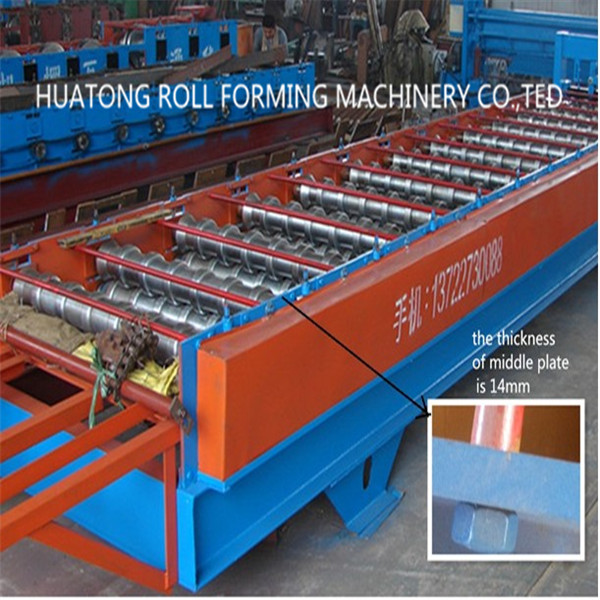

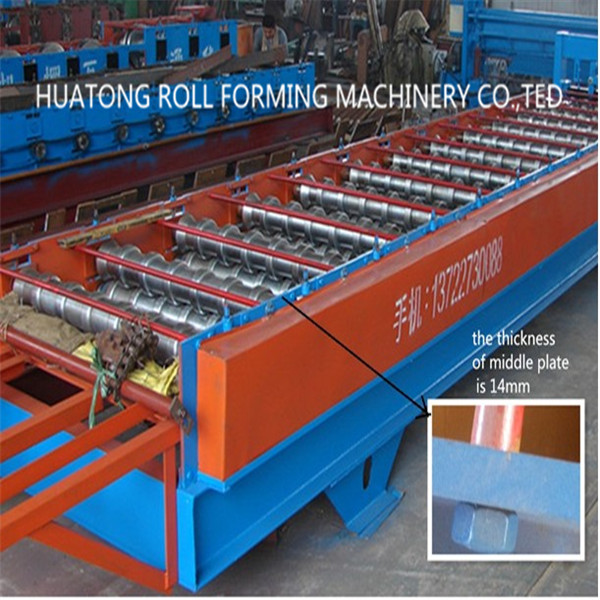

Thickness of middle plate |

12mm

|

Step of forming roller |

9steps

|

Diameter of shaft (solid shaft) |

70mm

|

Material of shaft (solid shaft) |

(high grade) 45# Steel

|

Treatment of roller |

quenched and tempered treatment, hard chromized coated 0.05-0.07mm

|

Drive type of roll forming machine |

drive by chain |

Chain |

25.4MM

|

Bearing |

6210high grade)

|

Reducer : |

5# cycloid reducer (high grade)

|

Power of main motor |

3KW

|

Voltage |

380V/50Hz/3phase

|

Line speed : |

about 9 m/min

|

Feeding width |

1000mm

|

Suitable coil thickness |

accepted thickness for steel coil is 0.3mm-1mm.

|

Motor power of hydraulic station |

3kw

|

Oil pump of hydraulic station |

gear oil pump (high grade)

|

Hydraulic cutting: |

cutting controlled by PLC

|

Accuracy of cutting |

+/- 2mm

|

Razor blades material |

Cr12, quenching 58-62 °. |

Weight of main forming machine : |

About3.65T

|

Electrically controlled system |

entire machine controlled by PLC

|

PLC |

DELTA(TAIWAN)

|

Frequency converter |

DELTA(TAIWAN) |

Encoder : |

RUI PU(high grade)

|

Controlling desktop : |

text panel screen(high grade) |

Electrical parts |

DELIXI or CHINT

|

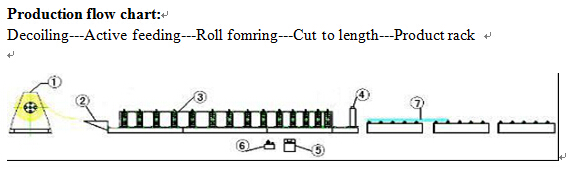

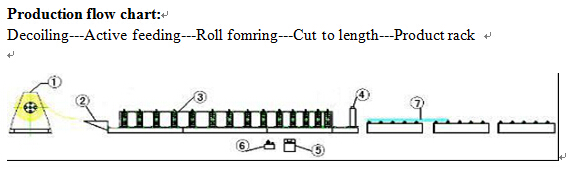

We know there are many companies you can choose, and maybe you think our price is higher than others, so I will introduce the different between our products and others. And how to choose the good machine. And why ours is higher.

First ,our shaft is solid, low price is hollow ,the use steel pipe instead of shaft. The shaft is one of the most important about the machine, we know it main press the plate, if the shaft is low quality, it can’t bear the pressure ,so it’s easy to broke. So this is one about our high price, we ensure the quality.

Our shaft is 45# steel, quenching and tempering treatment, low price is ordinary steel and no quenching and tempering treatment, and our roller is bigger than low price machine, and the treatment of roller surface is hard chromize coated 0.05-0.07mm, low price is 0.01-0.03mm even they paint silver powder instead of chromize coated

Our main frame is 25# I beam, others often small than us or use the H . This frame is the main frame, it nearly bear the whole weight, so it must be strong. And we use the I beam so that running is steady and reliable.

Our middle plate is 14, low price is 10-12. The middle plate bear the shaft. If it too thin ,it can’t bear the shaft for long time. The result is broken.

The machines will be ready within 30days from receipt of down payment as well as approval of sales contract, technical scheme and profile drawing. The shipment will be made within 10 days after the seller receives the balance by T/T.

30% of the contract amount as down payment after signed the contract; the balance is to be paid by T/T before shipment. Installation charge is to be paid before installation by T/T

our purpose :take the quality to the first,must let you satisfy ,to reach the common benefit,built long fridenly relationship for us.

so if you are interested in our products,please don't hesitate to contract me.

.png) Contact Now

Contact Now