Product Description

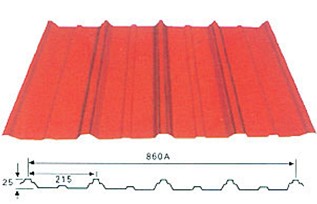

Profile:

25-215-860

1) Wave height : 25mm

2) Centre to centre distance between two waves : 215mm

3) Effective width : 860mm

4) Feeding width : 1000mm

5) Thickness of formed steel : 0.3mm-0.8mm

6) Material of coil or plate : color steel sheet

7) Use of finished product : roof panel or wall panel

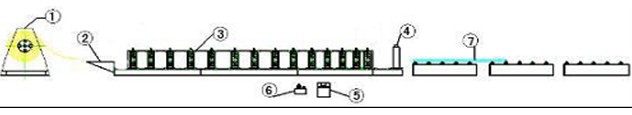

Name of production line:

HT 25-215-860full automatic roll forming machine line

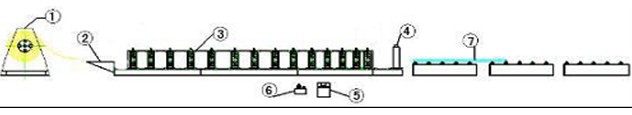

Production flow chart:

Decoiling---Active feeding---Roll forming---Cut to length---Product rack

Machine componets of full line:

(1) Manualun-coiler 1 set

(2) Feeding device 1 set

(3) Roll forming M/C 1 set

(4) Hydraulic cutter 1set

(5) PLC control system 1 set

(6) Hydraulic station 1 set

(7) Product rack (un-powered) 1 set

Technical specification: ( Photos just for reference )

(1) Manual un-coiler:

Unpowered, single head, to support and uncoil the steel coil, tenses the coil by manual, it is convenient for the workers to operate.

The coil inner diameter: φ450-550mm;

Max. outer coil diameter: φ1000mm-1250mm

The max capacity: 5T

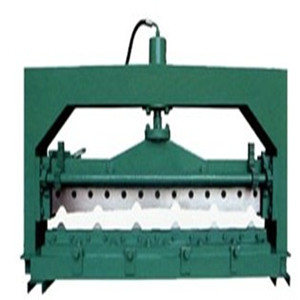

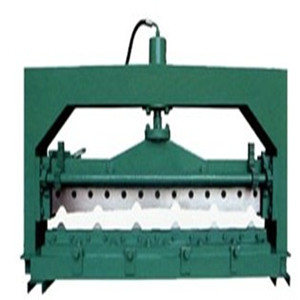

(2) Roll forming machine

We designed the parameters of roll forming machine for you as follow :

(1) Material of frame : (high grade) 250mm H shape steel welding

(2) Thickness of middle plate : 12mm

(3) Step of forming roller : 11steps

(4) Diameter of shaft (solid shaft): 70mm

(5) Material of shaft (solid shaft): (high grade) 45# Steel,quenching and tempering treatment

(6) Material of roller: 45# Steel

(7) Treatment of roller : hard chromize coated

(8) Drive type of roll forming machine : drive by chain

(9) Chain : 19.05 mm (high grade)

(10) Bearing : 6210 (high grade)

(11) Reducer : 4# cycloid reducer (high grade)

(12) Power of main motor : 3KW

(13) Voltage : 380V/50Hz/3phase

(14) Line speed : about 0-9 m/min

(15) Motor power of hydraulic station : 2.2kw

(16) Oil pump of hydraulic station : gear oil pump (high grade)

(17) Hydraulic cutting: cutting controlled by PLC

(18) Accuracy of cutting : +/- 2mm

(19) Razor blades material : Cr12, quenching 58-62 °.

(20) Appearance size of main forming machine : 5.6m (length)*1.3m (width) *1.3m (height)

(21) Electrically controlled system : entire machine controlled by PLC

(22) PLC : DELTA(TAIWAN)

(23) Frequency converter : DELTA(TAIWAN)

(24) Frequency converter power : 3.7KW

(25) Encoder : RUI PU(high grade)

(26) Controlling desktop : text panel screen(high grade)

(27) Electrical parts : DELIXI or CHINT

(3) Hydraulic Cutting

Hydraulic cutting,

Post cut, stop to cut,

The cutting blade material is Cr12,

The cutting tolerance:±2.0mm

(4) Hydraulic system

Supply the power for cutting.

Oil pump for hydraulic system

Type : gear oil pump

Brand : SDH (SHANG HAI )

Type : F316

Displacement : 16ml / r

Pressure : 20Mpa

(5) Eletric control system:

PLC control the whole line.

Human-machine interface, whirl encoder calcaulates the length, the touch screen sets the length.

You can set lots of data one time. Frequency adjusts speed, it has auto adjustment function

Transducer drives the main machine, it has E-stop button, which promise the safe running.

(6) Product rack:

In order to collect the final product, it is conveniently for workers to stack.

Note : we can customize the design and fabrication on the particular type of machine according to the request of customer.

.png) Contact Now

Contact Now