Product Description

High efficient steel press molding roll forming machine

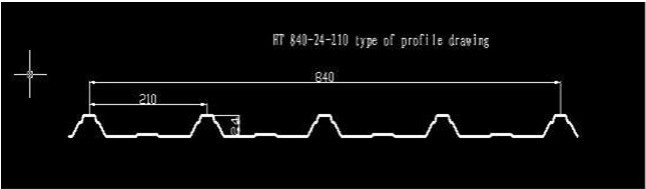

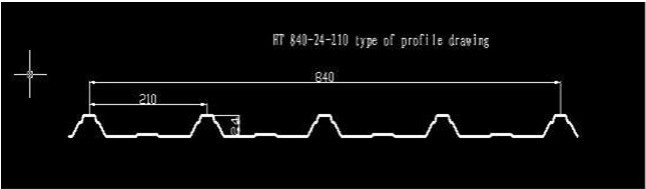

1. Product drawing :

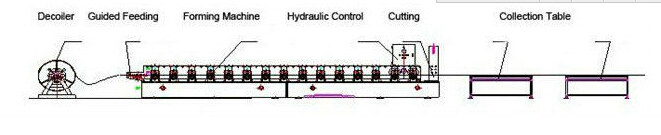

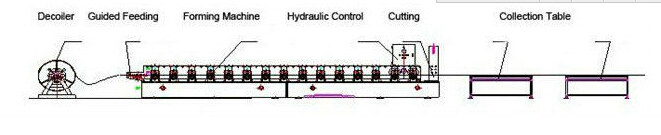

2. Production flow chart :

3. Technical Parameters :

No |

Item |

Parameter |

Note |

1 |

Suitable

Material

|

Type |

Metal Sheet |

Customized Specs Acceptable

|

|

Customized Profile |

Thickness |

0.3-0.8mm |

2 |

Product

Specs

|

Cover width |

Customized Profile |

|

Length |

Any length |

|

|

3

|

Power

Specs

|

Type |

380V/3PH/50HZ |

Up to Practical Profile |

Main Motor |

As per design |

Hydraulic |

As per design |

4 |

Machine

Specs

|

Transmission |

Chain and Sprocket |

|

Structure |

Wall Plate |

|

Shafter |

No.45 steel tempered |

|

Rollers |

No.45 steel chrome coated |

Cr12 or other acceptable |

Cutting Blade |

Cr12 quenched |

|

Press Mould |

Cr12 quenched |

|

Punch Mould |

Cr12 quenched |

|

5 |

Working

Capacity

|

Forming Speed |

0-20m/min |

Higher Speed Solution Available |

Working Speed |

Up to Length-set Cutting |

6 |

Manual

Decoiler

(Optional)

|

Type |

Hydraulic |

|

Max. Capacity |

5 T |

|

Suitable coil OD |

1200mm |

|

Suitable coil ID |

508/610mm |

|

Max Coil width |

1250mm |

|

7 |

Forming Stand |

8-30 |

Up to Practical Profile |

8 |

Forming Shaft Diameter |

55-100mm |

Up to Practical Profile |

9 |

Type of Cutting |

Length-set cutting after roll formed |

Pre-cutting acceptable |

10 |

Control System |

DELTA PLC and Inverter |

|

11 |

Output Supporter |

2 Pcs Simple Supporter |

|

4. Main roof roll forming machine :

5. PLC control system (touch screen panel) :

After-sales service:

We provide the technical support for whole life of our machines.

If you need, we could arrange our technical staff to go abroad.

Your inquiry is welcome!Please click here!

.png) Contact Now

Contact Now