Product Description

C steel purline roll forming machine

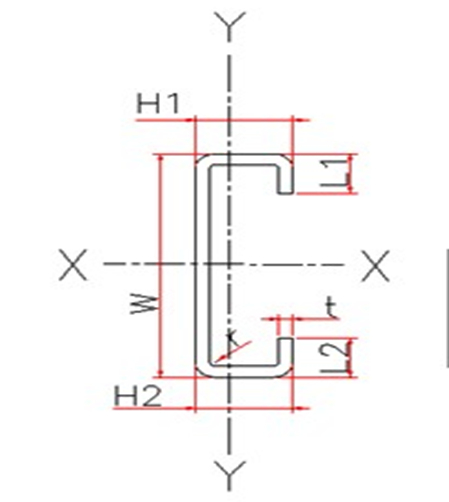

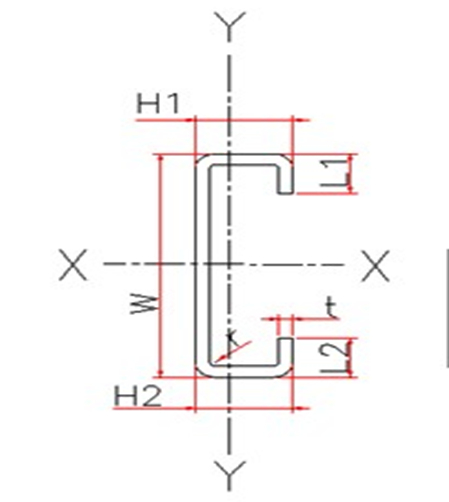

|

Max |

Min |

W |

80mm |

300mm |

H1 and H2 |

40mm |

100mm |

L1 and L2 |

10mm |

20mm |

Thickness |

2.0mm |

3.0mm |

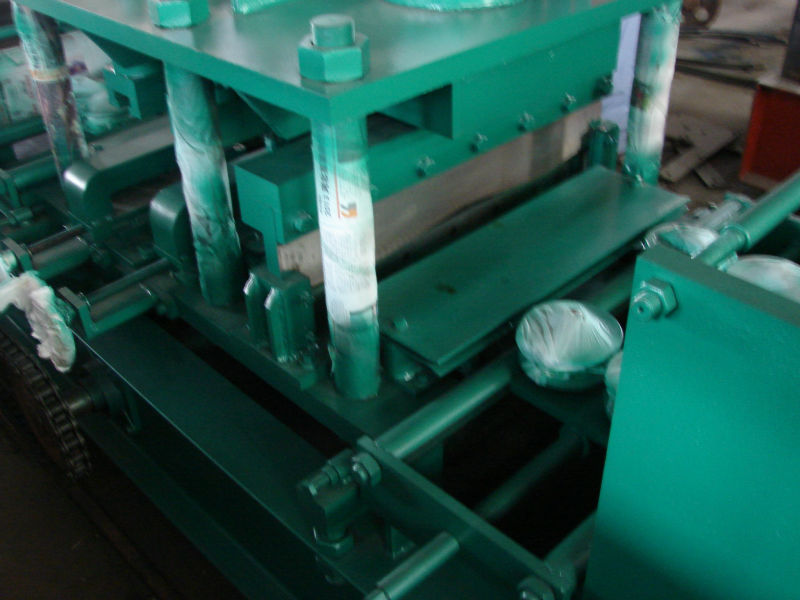

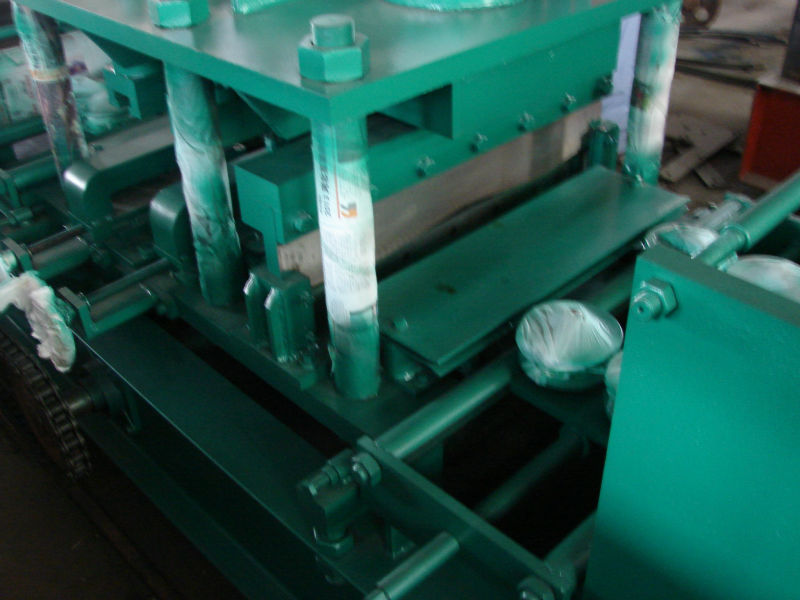

Automatic Building Material Steel Purline Making Machine

1) Material of frame : (high grade) 360mm H shape steel welding

2) Thickness of middle plate : 25mm

3) Step of forming roller : 12steps

4) Diameter of shaft (solid shaft): 95mm

5) Material of shaft (solid shaft): (high grade) 45# Steel

6) Material of roller: GCr15

7) Treatment of roller : quenched and temperedtreatment,hard chromize coated 0.05-0.07mm

8) Drive type of roll forming machine : drive by chain

9) Chain : 50.8 mm (high grade)

10) Bearing : 6312 (high grade)

11) Reducer : 8# cycloid reducer (high grade)

12) Power of main motor : 11KW

13) Voltage : 380V/50Hz/3phase

14) Line speed : about 9-12 m/min

15) Feeding width : 166mm-516mm

16) Suitable coil thickness : accepted thickness for steel coil is 1.0mm-3.0mm.

17) Motor power of hydraulic station : 5.5kw

18) Oil pump of hydraulic station : gear oil pump (high grade)

19) Hydraulic cutting: cutting controlled by PLC

20) Accuracy of cutting : +/- 2mm

21) Razor blades material : Cr12, quenching 58-62 °.

22) Appearance size of main forming machine : 8.0m (length)*1.8m (width) *1.3m (height)

23) Weight of main forming machine : about 7.0T

24) Electrically controlled system : entire machine controlled by PLC

25) PLC : DELTA(TAIWAN)

26) Frequency converter : DELTA(TAIWAN)

27) Frequency converter power : 5.5KW

28) Encoder : RUI PU(high grade)

29) Controlling desktop : text panel screen(high grade)

30) Electrical parts : DELIXI or CHINT

31) Leveing syetem before forming :

Steps of leveiling roller : 7steps

Diameter of shaft : 95mm

Company

Why to choose our roll forming machine?

Over 20 years experience, ISO certificate, near Tianjin port, this is how we keep good quality and competitive prices for global valued customers. And OEM / ODM ,Customers` Design ,Size,Color&Logo are accepted.

After-sales service:

1.We provide the technical support for whole life of our machines.

2.If buyers need the technician to go abroad ,we will arrange the technician,but the buyers should take all the cost,including visa,roundtrip ticket etc.

Note : we can customize the design and fabrication on the particular type of machine according to the request of customer.

.png) Contact Now

Contact Now