Product Description

C steel purline roll forming machine

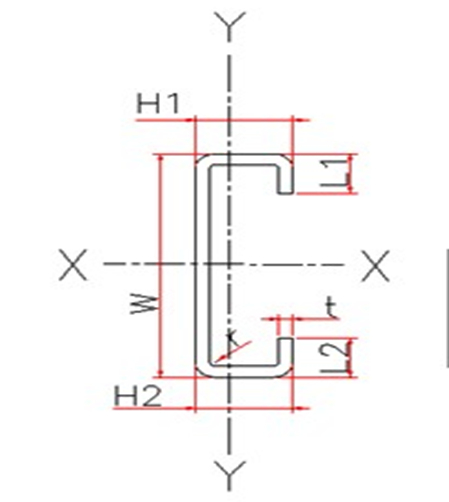

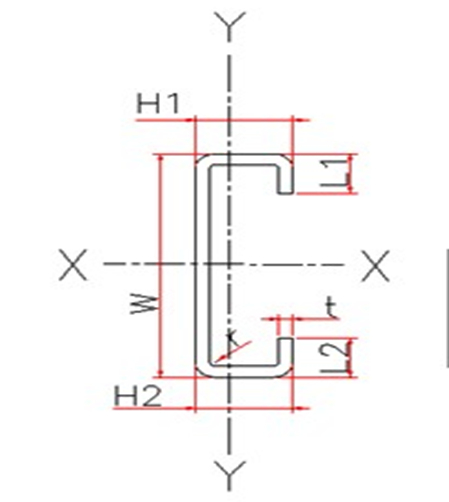

|

Max |

Min |

W |

80mm |

300mm |

H1 and H2 |

40mm |

100mm |

L1 and L2 |

10mm |

20mm |

Thickness |

2.0mm |

3.0mm |

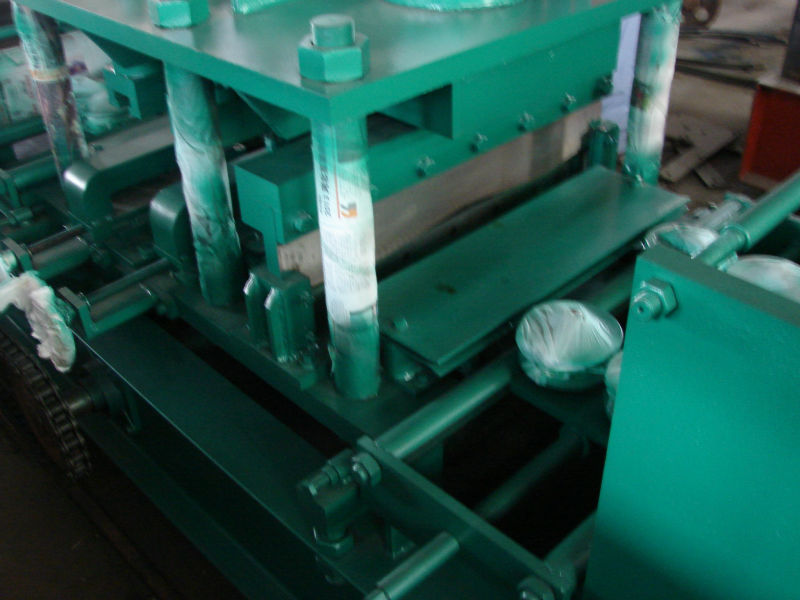

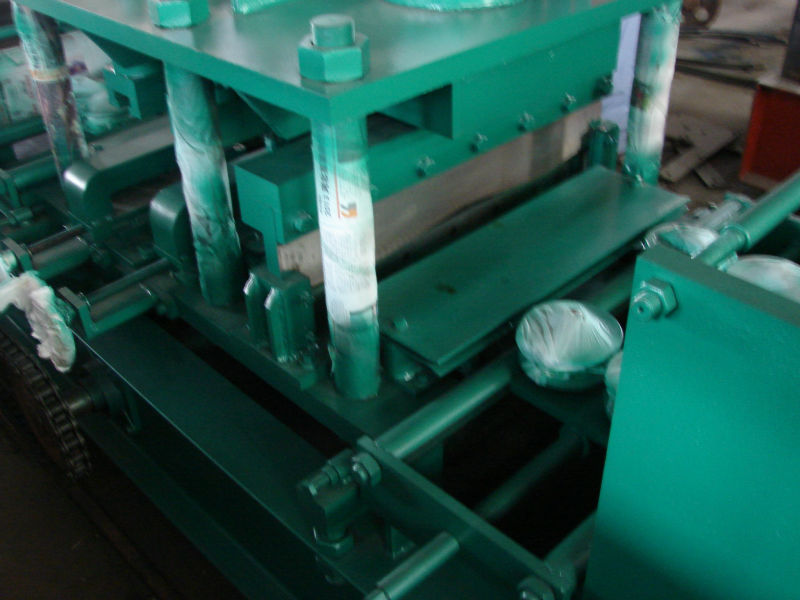

1) Material of frame : (high grade) 360mm H shape steel welding

2) Thickness of middle plate : 25mm

3) Step of forming roller : 12steps

4) Diameter of shaft (solid shaft): 95mm

5) Material of shaft (solid shaft): (high grade) 45# Steel

6) Material of roller: GCr15

7) Treatment of roller : quenched and temperedtreatment,hard chromize coated 0.05-0.07mm

8) Drive type of roll forming machine : drive by chain

9) Chain : 50.8 mm (high grade)

10) Bearing : 6312 (high grade)

11) Reducer : 8# cycloid reducer (high grade)

12) Power of main motor : 11KW

13) Voltage : 380V/50Hz/3phase

14) Line speed : about 9-12 m/min

15) Feeding width : 166mm-516mm

16) Suitable coil thickness : accepted thickness for steel coil is 1.0mm-3.0mm.

17) Motor power of hydraulic station : 5.5kw

18) Oil pump of hydraulic station : gear oil pump (high grade)

19) Hydraulic cutting: cutting controlled by PLC

20) Accuracy of cutting : +/- 2mm

21) Razor blades material : Cr12, quenching 58-62 °.

22) Appearance size of main forming machine : 8.0m (length)*1.8m (width) *1.3m (height)

23) Weight of main forming machine : about 7.0T

24) Electrically controlled system : entire machine controlled by PLC

25) PLC : DELTA(TAIWAN)

26) Frequency converter : DELTA(TAIWAN)

27) Frequency converter power : 5.5KW

28) Encoder : RUI PU(high grade)

29) Controlling desktop : text panel screen(high grade)

30) Electrical parts : DELIXI or CHINT

31) Leveing syetem before forming :

Steps of leveiling roller : 7steps

Diameter of shaft : 95mm

Company

Note : we can customize the design and fabrication on the particular type of machine according to the request of customer.

.png) Contact Now

Contact Now